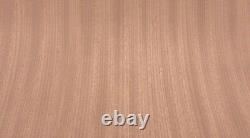

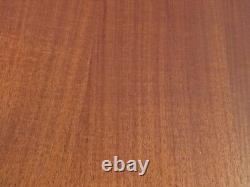

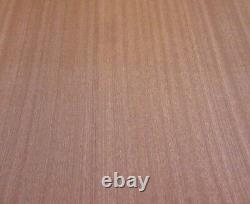

Sapele Ribbon Mahogany wood veneer 48 x 96 on wood backer A grade 1/25 thick

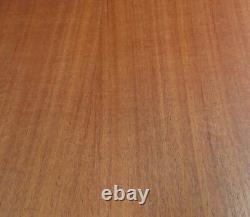

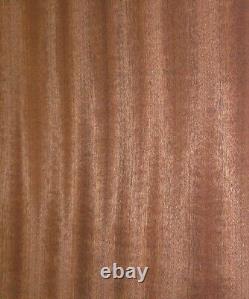

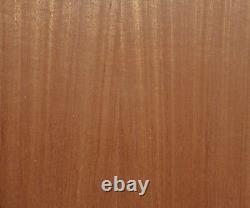

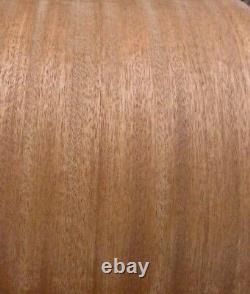

African Ribbon Sapele Mahogany wood veneer 48" x 96" with wood backer 4' x 8' x 1/25 thickness A grade quality. Pictures are representative and actual product will vary in color and grain since this is a natural product. Wood backer is sometimes preferred over paper backer because it is thicker and may hide minor surface imperfections and bond better. Some photos may show other sizes, customer projects, and wet or finished veneer.

Each sheet is carefully inspected and packaged by our company. Other sizes, backers, edgebanding and raw veneer are available. Trust the experience, knowledge, and reputation that has served the wood industry and novices since 1995.

Most pictures have been temporarily wet on the lower portion of the veneer to show what the grain may look like when finish is added. Color adjustments have been made to show the color as best as is possible. It is impossible to get photos exactly correct in color, but we have made an effort to do so. Backed products come with complete application instructions that are simple and clear. For raw veneer or un-backed products, we suggest using the Internet to see what advice is available as opinions vary on the best way to handle that product.Below is general information for most of our products. Make sure you check the listing to see which applies to the above product in particular. (will not always be exactly correct, but relatively close). Raw plain veneer with no backing = 1/32"-1/42". Generally cut with a razor/box knife or similar tools and some type of straight edge.

Paper-backed and wood-backed veneers are generally applied with contact cement. Raw plain veneer is applied with white or yellow wood glue and must have pressure applied while drying. Most any conventional finishing products can be used with veneer that is applied correctly. Sometimes veneers have minor splits or tears in them. These are usually taped or repaired in some manner and shouldn't impact overall quality or satisfaction. There may also be some minor wood filler used to fill cracks and other crevices that may exist. Wood products are rarely perfect and some consideration of that may be needed occasionally since this is a natural product and is rarely ever perfect. Some sanding is usually required before finishing to prepare the surface for a finish and occasionally to remove veneer tape, splice glue, or some other imperfection.